Manifold vs Ported vacuum

#1

Manifold vs Ported vacuum

I feel like this has probably been asked hundreds of times but what is the best for power and what is best for mpg. Is there a way to have both mpg and power in respect of the vacuum advance that is. Does vac advance contribute to total timing?So where should I hook up my vac advance?

#2

Vacuum advance connects to Ported Vacuum, NOT manifold vacuum.

Where I get/got confused is what "ported vacuum" means. People will call a vacuum switch in a radiator line ported vacuum. When the water heats, the switch opens and turns on vacuum. That (IMHO) is NOT ported vacuum, that is a switched manifold vacuum.

Ported vacuum comes from the carb BEFORE the throttle plate. The throttle plate is between the vacuum tap and manifold pressure. That way, at or near idle, the vacuum from the manifold is blocked so that you get near 0 vacuum. As you accelerate, the throttle plate opens and you get near whatever the manifold vacuum pressure is. That is what both the EGR and vacuum advance want to see.

If you connect to manifold vacuum directly, the advance will see about 20 inches of pressure and you do not want that kind of advance at idle.

Where I get/got confused is what "ported vacuum" means. People will call a vacuum switch in a radiator line ported vacuum. When the water heats, the switch opens and turns on vacuum. That (IMHO) is NOT ported vacuum, that is a switched manifold vacuum.

Ported vacuum comes from the carb BEFORE the throttle plate. The throttle plate is between the vacuum tap and manifold pressure. That way, at or near idle, the vacuum from the manifold is blocked so that you get near 0 vacuum. As you accelerate, the throttle plate opens and you get near whatever the manifold vacuum pressure is. That is what both the EGR and vacuum advance want to see.

If you connect to manifold vacuum directly, the advance will see about 20 inches of pressure and you do not want that kind of advance at idle.

#3

Typically the vacuum advance runs to ported vacuum. This is the ideal case 95% of the time. However, there are some cases where (smog) motors with extremely low initial timing specifications will have the advance sourced from manifold vacuum from the factory.

The "ported" in "ported vacuum switch" (PVS) is named as such because the switch itself has physical ports; it's not meant to infer any kind of vacuum source (it's a coincidence). However, these switches are not always sourced from manifold vacuum; in fact the majority of the time they typically are sourced from ported vacuum. An example is the EGR valve - the EGR valve should receive ported vacuum when the engine is at operating temperature, and no vacuum when the engine is below operating temperature. As such, the EGR is sourced from ported vacuum, through a ported vacuum switch (but the switch is not called a "ported" switch because of its vacuum source).

However, some engines have a three-port vacuum switch connected to the vacuum advance. Below operating temperature, the vacuum advance is sourced from manifold vacuum. Above a certain temperature, the vacuum advance is sourced from ported vacuum. In this case, multiple vacuum sources are routed to the advance, yet it's still called a "ported" vacuum switch (again, because of its physical construction, not because of any one vacuum source that runs to it). In these instances, either ported or manifold vacuum is routed to the vacuum advance, depending on temperature.

The "ported" in "ported vacuum switch" (PVS) is named as such because the switch itself has physical ports; it's not meant to infer any kind of vacuum source (it's a coincidence). However, these switches are not always sourced from manifold vacuum; in fact the majority of the time they typically are sourced from ported vacuum. An example is the EGR valve - the EGR valve should receive ported vacuum when the engine is at operating temperature, and no vacuum when the engine is below operating temperature. As such, the EGR is sourced from ported vacuum, through a ported vacuum switch (but the switch is not called a "ported" switch because of its vacuum source).

However, some engines have a three-port vacuum switch connected to the vacuum advance. Below operating temperature, the vacuum advance is sourced from manifold vacuum. Above a certain temperature, the vacuum advance is sourced from ported vacuum. In this case, multiple vacuum sources are routed to the advance, yet it's still called a "ported" vacuum switch (again, because of its physical construction, not because of any one vacuum source that runs to it). In these instances, either ported or manifold vacuum is routed to the vacuum advance, depending on temperature.

#4

Post #2 Actually it's just the opposite. If you have ever put a timing light on a engine with the vacuum advance hooked up you will quickly see why you have to remove and plug the vacuum line, there is full vacuum at idle and while crusing. The only time it shuts off is under a load, when you don't want excessive timing.

#5

Post #2 Actually it's just the opposite. If you have ever put a timing light on a engine with the vacuum advance hooked up you will quickly see why you have to remove and plug the vacuum line, there is full vacuum at idle and while crusing. The only time it shuts off is under a load, when you don't want excessive timing.

The factory procedure calls for plugging the line to the advance to cover cases where the vacuum advance is connected to manifold vacuum, and to cover cases where the vacuum advance is advancing the timing due to slight vacuum at high idle speeds.

#6

#7

Very thorough explanation, fmc400!

Most people throw these ported vacuum switches away, but they do help with certain driving conditions. If you don't have any, simply run a vacuum hose from your distributor vacuum advance to the ported vacuum source on your carburetor.

If you have automatic transmission, you will see why you need to use ported vacuum for the vacuum advance as soon as you put it in gear.

To add to the confusion on ported vacuum switches, I have a red 3-port vacuum switch on my truck that is connected to the thermostat housing that is rated for 225 degrees. The distributor connects to the center port, and normal vacuum advance is supplied from a ported vacuum source. If the engine temperature goes above 225 degrees, the ported vacuum sources is blocked off and the ported vacuum switch uses manifold vacuum instead. This is to raise the idle, which in turn will turn the water pump and fan faster for extra cooling.

The Ford Mustangs in the mid 1980s used a different 3-port vacuum switch for its vacuum advance. This switch is green and is rated for 180 degrees. Here the vacuum advance is sourced through manifold vacuum below 180 degrees, and then the ported vacuum switch will block manifold vacuum and source ported vacuum instead. This is to help the engine get up to operating temperatures faster, and this in turn helps emissions.

Most people throw these ported vacuum switches away, but they do help with certain driving conditions. If you don't have any, simply run a vacuum hose from your distributor vacuum advance to the ported vacuum source on your carburetor.

If you have automatic transmission, you will see why you need to use ported vacuum for the vacuum advance as soon as you put it in gear.

To add to the confusion on ported vacuum switches, I have a red 3-port vacuum switch on my truck that is connected to the thermostat housing that is rated for 225 degrees. The distributor connects to the center port, and normal vacuum advance is supplied from a ported vacuum source. If the engine temperature goes above 225 degrees, the ported vacuum sources is blocked off and the ported vacuum switch uses manifold vacuum instead. This is to raise the idle, which in turn will turn the water pump and fan faster for extra cooling.

The Ford Mustangs in the mid 1980s used a different 3-port vacuum switch for its vacuum advance. This switch is green and is rated for 180 degrees. Here the vacuum advance is sourced through manifold vacuum below 180 degrees, and then the ported vacuum switch will block manifold vacuum and source ported vacuum instead. This is to help the engine get up to operating temperatures faster, and this in turn helps emissions.

Trending Topics

#8

Reading these posts rekindles a question I raised when I switched my dizzy to a DUI and the instructions specifically said to run it on manifold port if your motor could handle it as it kept the plugs cleaner. I even called them to verify it. I am currently running it on manifold and it does appear to run great, but still have an uneazy feeling about that concept.

#9

I bought a custom-curved Duraspark distributor from Performance Distributors (same company that makes the GM-styled DUI) and the directions specifically said to run ported vacuum, and to run a higher ignition timing. I am running mine on ported vacuum with the timing set to 12* BTDC and the idle at 650 RPMs. Ported vacuum is what Ford used for vacuum advance most of the time. If you have an automatic transmission, you will find that it is very difficult to get a low enough and consistent idle on manifold vacuum and your truck will SLAM into gear.

I have heard that most GMs used manifold vacuum, but what do they know?

I have heard that most GMs used manifold vacuum, but what do they know?

#10

I too run ported vacuum, always have, it works best for my particular setup, but there is a valid argument to be made on behalf of manifold vacuum, this article posted below has pretty much made the rounds on most online automotive forums...

TIMING AND VACUUM ADVANCE 101

The most important concept to understand is that lean mixtures, such as at idle and steady highway cruise, take longer to burn than rich mixtures; idle in particular, as idle mixture is affected by exhaust gas dilution. This requires that lean mixtures have "the fire lit" earlier in the compression cycle (spark timing advanced), allowing more burn time so that peak cylinder pressure is reached just after TDC for peak efficiency and reduced exhaust gas temperature (wasted combustion energy). Rich mixtures, on the other hand, burn faster than lean mixtures, so they need to have "the fire lit" later in the compression cycle (spark timing retarded slightly) so maximum cylinder pressure is still achieved at the same point after TDC as with the lean mixture, for maximum efficiency.

The centrifugal advance system in a distributor advances spark timing purely as a function of engine rpm (irrespective of engine load or operating conditions), with the amount of advance and the rate at which it comes in determined by the weights and springs on top of the autocam mechanism. The amount of advance added by the distributor, combined with initial static timing, is "total timing" (i.e., the 34-36 degrees at high rpm that most engines like). Vacuum advance has absolutely nothing to do with total timing or performance, as when the throttle is opened, manifold vacuum drops essentially to zero, and the vacuum advance drops out entirely; it has no part in the "total timing" equation.

At idle, the engine needs additional spark advance in order to fire that lean, diluted mixture earlier in order to develop maximum cylinder pressure at the proper point, so the vacuum advance can (connected to manifold vacuum, not "ported" vacuum - more on that aberration later) is activated by the high manifold vacuum, and adds about 15 degrees of spark advance, on top of the initial static timing setting (i.e., if your static timing is at 10 degrees, at idle it's actually around 25 degrees with the vacuum advance connected). The same thing occurs at steady-state highway cruise; the mixture is lean, takes longer to burn, the load on the engine is low, the manifold vacuum is high, so the vacuum advance is again deployed, and if you had a timing light set up so you could see the balancer as you were going down the highway, you'd see about 50 degrees advance (10 degrees initial, 20-25 degrees from the centrifugal advance, and 15 degrees from the vacuum advance) at steady-state cruise (it only takes about 40 horsepower to cruise at 50mph).

When you accelerate, the mixture is instantly enriched (by the accelerator pump, power valve, etc.), burns faster, doesn't need the additional spark advance, and when the throttle plates open, manifold vacuum drops, and the vacuum advance can returns to zero, retarding the spark timing back to what is provided by the initial static timing plus the centrifugal advance provided by the distributor at that engine rpm; the vacuum advance doesn't come back into play until you back off the gas and manifold vacuum increases again as you return to steady-state cruise, when the mixture again becomes lean.

The key difference is that centrifugal advance (in the distributor autocam via weights and springs) is purely rpm-sensitive; nothing changes it except changes in rpm. Vacuum advance, on the other hand, responds to engine load and rapidly-changing operating conditions, providing the correct degree of spark advance at any point in time based on engine load, to deal with both lean and rich mixture conditions. By today's terms, this was a relatively crude mechanical system, but it did a good job of optimizing engine efficiency, throttle response, fuel economy, and idle cooling, with absolutely ZERO effect on wide-open throttle performance, as vacuum advance is inoperative under wide-open throttle conditions. In modern cars with computerized engine controllers, all those sensors and the controller change both mixture and spark timing 50 to 100 times per second, and we don't even HAVE a distributor any more - it's all electronic.

Now, to the widely-misunderstood manifold-vs.-ported vacuum aberration. After 30-40 years of controlling vacuum advance with full manifold vacuum, along came emissions requirements, years before catalytic converter technology had been developed, and all manner of crude band-aid systems were developed to try and reduce hydrocarbons and oxides of nitrogen in the exhaust stream. One of these band-aids was "ported spark", which moved the vacuum pickup orifice in the carburetor venturi from below the throttle plate (where it was exposed to full manifold vacuum at idle) to above the throttle plate, where it saw no manifold vacuum at all at idle. This meant the vacuum advance was inoperative at idle (retarding spark timing from its optimum value), and these applications also had VERY low initial static timing (usually 4 degrees or less, and some actually were set at 2 degrees AFTER TDC). This was done in order to increase exhaust gas temperature (due to "lighting the fire late") to improve the effectiveness of the "afterburning" of hydrocarbons by the air injected into the exhaust manifolds by the A.I.R. system; as a result, these engines ran like crap, and an enormous amount of wasted heat energy was transferred through the exhaust port walls into the coolant, causing them to run hot at idle - cylinder pressure fell off, engine temperatures went up, combustion efficiency went down the drain, and fuel economy went down with it.

If you look at the centrifugal advance calibrations for these "ported spark, late-timed" engines, you'll see that instead of having 20 degrees of advance, they had up to 34 degrees of advance in the distributor, in order to get back to the 34-36 degrees "total timing" at high rpm wide-open throttle to get some of the performance back. The vacuum advance still worked at steady-state highway cruise (lean mixture = low emissions), but it was inoperative at idle, which caused all manner of problems - "ported vacuum" was strictly an early, pre-converter crude emissions strategy, and nothing more.

What about the Harry high-school non-vacuum advance polished billet "whizbang" distributors you see in the Summit and Jeg's catalogs? They're JUNK on a street-driven car, but some people keep buying them because they're "race car" parts, so they must be "good for my car" - they're NOT. "Race cars" run at wide-open throttle, rich mixture, full load, and high rpm all the time, so they don't need a system (vacuum advance) to deal with the full range of driving conditions encountered in street operation. Anyone driving a street-driven car without manifold-connected vacuum advance is sacrificing idle cooling, throttle response, engine efficiency, and fuel economy, probably because they don't understand what vacuum advance is, how it works, and what it's for - there are lots of long-time experienced "mechanics" who don't understand the principles and operation of vacuum advance either, so they're not alone.

Vacuum advance calibrations are different between stock engines and modified engines, especially if you have a lot of cam and have relatively low manifold vacuum at idle. Most stock vacuum advance cans aren’t fully-deployed until they see about 15” Hg. Manifold vacuum, so those cans don’t work very well on a modified engine; with less than 15” Hg. at a rough idle, the stock can will “dither” in and out in response to the rapidly-changing manifold vacuum, constantly varying the amount of vacuum advance, which creates an unstable idle. Modified engines with more cam that generate less than 15” Hg. of vacuum at idle need a vacuum advance can that’s fully-deployed at least 1”, preferably 2” of vacuum less than idle vacuum level so idle advance is solid and stable; the Echlin #VC-1810 advance can (about $10 at NAPA) provides the same amount of advance as the stock can (15 degrees), but is fully-deployed at only 8” of vacuum, so there is no variation in idle timing even with a stout cam.

For peak engine performance, driveability, idle cooling and efficiency in a street-driven car, you need vacuum advance, connected to full manifold vacuum. Absolutely. Positively. Don't ask Summit or Jeg's about it – they don’t understand it, they're on commission, and they want to sell "race car" parts.

TIMING AND VACUUM ADVANCE 101

The most important concept to understand is that lean mixtures, such as at idle and steady highway cruise, take longer to burn than rich mixtures; idle in particular, as idle mixture is affected by exhaust gas dilution. This requires that lean mixtures have "the fire lit" earlier in the compression cycle (spark timing advanced), allowing more burn time so that peak cylinder pressure is reached just after TDC for peak efficiency and reduced exhaust gas temperature (wasted combustion energy). Rich mixtures, on the other hand, burn faster than lean mixtures, so they need to have "the fire lit" later in the compression cycle (spark timing retarded slightly) so maximum cylinder pressure is still achieved at the same point after TDC as with the lean mixture, for maximum efficiency.

The centrifugal advance system in a distributor advances spark timing purely as a function of engine rpm (irrespective of engine load or operating conditions), with the amount of advance and the rate at which it comes in determined by the weights and springs on top of the autocam mechanism. The amount of advance added by the distributor, combined with initial static timing, is "total timing" (i.e., the 34-36 degrees at high rpm that most engines like). Vacuum advance has absolutely nothing to do with total timing or performance, as when the throttle is opened, manifold vacuum drops essentially to zero, and the vacuum advance drops out entirely; it has no part in the "total timing" equation.

At idle, the engine needs additional spark advance in order to fire that lean, diluted mixture earlier in order to develop maximum cylinder pressure at the proper point, so the vacuum advance can (connected to manifold vacuum, not "ported" vacuum - more on that aberration later) is activated by the high manifold vacuum, and adds about 15 degrees of spark advance, on top of the initial static timing setting (i.e., if your static timing is at 10 degrees, at idle it's actually around 25 degrees with the vacuum advance connected). The same thing occurs at steady-state highway cruise; the mixture is lean, takes longer to burn, the load on the engine is low, the manifold vacuum is high, so the vacuum advance is again deployed, and if you had a timing light set up so you could see the balancer as you were going down the highway, you'd see about 50 degrees advance (10 degrees initial, 20-25 degrees from the centrifugal advance, and 15 degrees from the vacuum advance) at steady-state cruise (it only takes about 40 horsepower to cruise at 50mph).

When you accelerate, the mixture is instantly enriched (by the accelerator pump, power valve, etc.), burns faster, doesn't need the additional spark advance, and when the throttle plates open, manifold vacuum drops, and the vacuum advance can returns to zero, retarding the spark timing back to what is provided by the initial static timing plus the centrifugal advance provided by the distributor at that engine rpm; the vacuum advance doesn't come back into play until you back off the gas and manifold vacuum increases again as you return to steady-state cruise, when the mixture again becomes lean.

The key difference is that centrifugal advance (in the distributor autocam via weights and springs) is purely rpm-sensitive; nothing changes it except changes in rpm. Vacuum advance, on the other hand, responds to engine load and rapidly-changing operating conditions, providing the correct degree of spark advance at any point in time based on engine load, to deal with both lean and rich mixture conditions. By today's terms, this was a relatively crude mechanical system, but it did a good job of optimizing engine efficiency, throttle response, fuel economy, and idle cooling, with absolutely ZERO effect on wide-open throttle performance, as vacuum advance is inoperative under wide-open throttle conditions. In modern cars with computerized engine controllers, all those sensors and the controller change both mixture and spark timing 50 to 100 times per second, and we don't even HAVE a distributor any more - it's all electronic.

Now, to the widely-misunderstood manifold-vs.-ported vacuum aberration. After 30-40 years of controlling vacuum advance with full manifold vacuum, along came emissions requirements, years before catalytic converter technology had been developed, and all manner of crude band-aid systems were developed to try and reduce hydrocarbons and oxides of nitrogen in the exhaust stream. One of these band-aids was "ported spark", which moved the vacuum pickup orifice in the carburetor venturi from below the throttle plate (where it was exposed to full manifold vacuum at idle) to above the throttle plate, where it saw no manifold vacuum at all at idle. This meant the vacuum advance was inoperative at idle (retarding spark timing from its optimum value), and these applications also had VERY low initial static timing (usually 4 degrees or less, and some actually were set at 2 degrees AFTER TDC). This was done in order to increase exhaust gas temperature (due to "lighting the fire late") to improve the effectiveness of the "afterburning" of hydrocarbons by the air injected into the exhaust manifolds by the A.I.R. system; as a result, these engines ran like crap, and an enormous amount of wasted heat energy was transferred through the exhaust port walls into the coolant, causing them to run hot at idle - cylinder pressure fell off, engine temperatures went up, combustion efficiency went down the drain, and fuel economy went down with it.

If you look at the centrifugal advance calibrations for these "ported spark, late-timed" engines, you'll see that instead of having 20 degrees of advance, they had up to 34 degrees of advance in the distributor, in order to get back to the 34-36 degrees "total timing" at high rpm wide-open throttle to get some of the performance back. The vacuum advance still worked at steady-state highway cruise (lean mixture = low emissions), but it was inoperative at idle, which caused all manner of problems - "ported vacuum" was strictly an early, pre-converter crude emissions strategy, and nothing more.

What about the Harry high-school non-vacuum advance polished billet "whizbang" distributors you see in the Summit and Jeg's catalogs? They're JUNK on a street-driven car, but some people keep buying them because they're "race car" parts, so they must be "good for my car" - they're NOT. "Race cars" run at wide-open throttle, rich mixture, full load, and high rpm all the time, so they don't need a system (vacuum advance) to deal with the full range of driving conditions encountered in street operation. Anyone driving a street-driven car without manifold-connected vacuum advance is sacrificing idle cooling, throttle response, engine efficiency, and fuel economy, probably because they don't understand what vacuum advance is, how it works, and what it's for - there are lots of long-time experienced "mechanics" who don't understand the principles and operation of vacuum advance either, so they're not alone.

Vacuum advance calibrations are different between stock engines and modified engines, especially if you have a lot of cam and have relatively low manifold vacuum at idle. Most stock vacuum advance cans aren’t fully-deployed until they see about 15” Hg. Manifold vacuum, so those cans don’t work very well on a modified engine; with less than 15” Hg. at a rough idle, the stock can will “dither” in and out in response to the rapidly-changing manifold vacuum, constantly varying the amount of vacuum advance, which creates an unstable idle. Modified engines with more cam that generate less than 15” Hg. of vacuum at idle need a vacuum advance can that’s fully-deployed at least 1”, preferably 2” of vacuum less than idle vacuum level so idle advance is solid and stable; the Echlin #VC-1810 advance can (about $10 at NAPA) provides the same amount of advance as the stock can (15 degrees), but is fully-deployed at only 8” of vacuum, so there is no variation in idle timing even with a stout cam.

For peak engine performance, driveability, idle cooling and efficiency in a street-driven car, you need vacuum advance, connected to full manifold vacuum. Absolutely. Positively. Don't ask Summit or Jeg's about it – they don’t understand it, they're on commission, and they want to sell "race car" parts.

#11

For another example the user ArdWrknTrk has a truck with a 460. The factory configuration on his truck uses a vacuum switch. During normal operating conditions it runs full manifold vacuum through a restrictor, and when if it starts to overheat (225F?); it switches to full manifold vacuum.

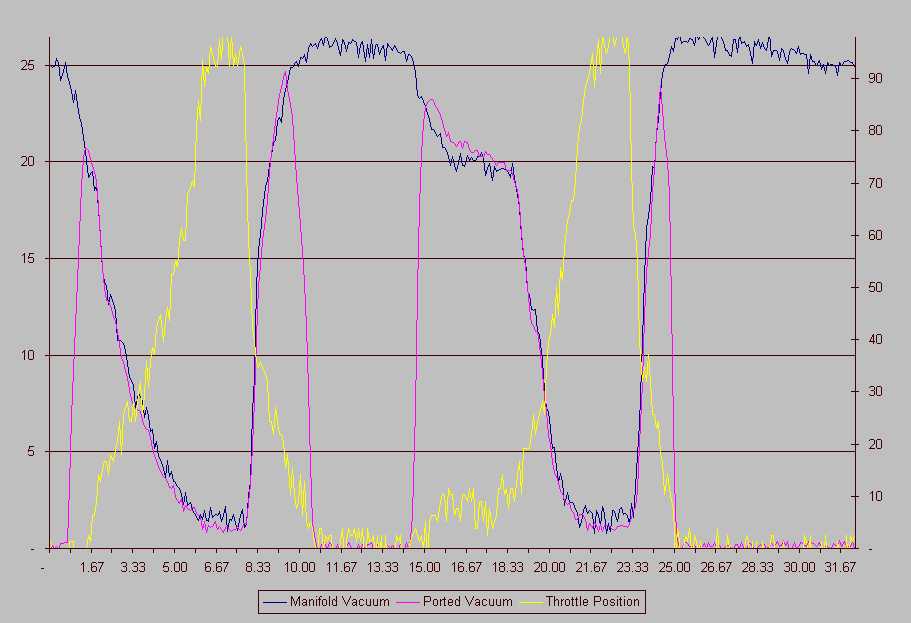

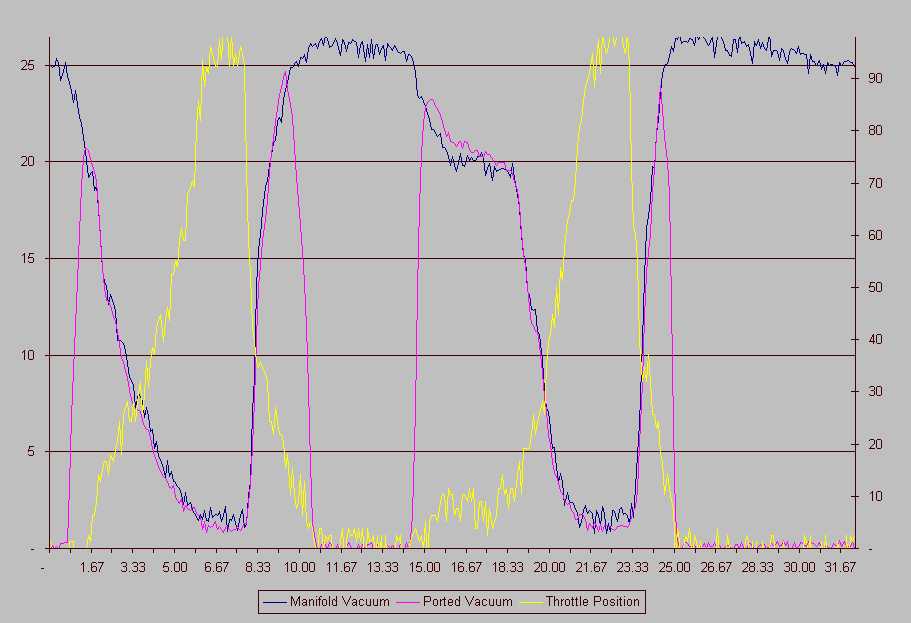

And for the icing on the cake here is proof that ported and full manifold sources pull a nearly identical vacuum, at any time except idle.

As you can see they follow each other very closely except when you see the throttle position go to 0.

And for the icing on the cake here is proof that ported and full manifold sources pull a nearly identical vacuum, at any time except idle.

As you can see they follow each other very closely except when you see the throttle position go to 0.

#12

Post #2 Actually it's just the opposite. If you have ever put a timing light on a engine with the vacuum advance hooked up you will quickly see why you have to remove and plug the vacuum line, there is full vacuum at idle and while crusing. The only time it shuts off is under a load, when you don't want excessive timing.

Ported vacume get's it's signal just a hair above the throttle plates and there is a slot that goes down the wall so that as the throttle is gradually opened from closed, it will start picking up and there is rapidly a point where ported vacume is then equal to manifold vacume below the throttle plates. If you are getting a good vacume signal at a ported vacume port on the carb at idle, your plates are opened up more to sustain the idle. The adjustment of float levels and idle restrictors and base timing may allow you to close it some and kill some of that signal.

Likewise, it may be that you have a hot rod cam that requires a higher idle setting on the carb to maintain idle. Some people have drilled 1/8" holes in each throttle plate to allow a nearer closed position to maintain idle. If you have to open the throttle plates too much with the idle stop screw you start loosing the ability to adjust idle misture with the idle mix screws once the plates move above the idle slots.

It may be that you have a carb with both ported and manifold vacume ports too. A manifold vacume port would blead below the throttle plates.

I have used both ported vacume on my distributor vac advance and manifold vacume at different times. Manifold vacume advances the distributor timing at idle, let's you close the throtrtle tighter, and can increase fuel mileage. That's how she's plumbed now. It works best for me maybe because of the cam choice I made in the late '80s (stock 351M with .484/.510 Crane Fireball cam, Edelbrock Performer intake, was Holley, now Edelbrock 600 cfm carb., advance spring kit which means I set mine for 34* total advance at elevated RPMs with vac unplugged .... I'll set the 400 up differently some). Manifold vacume let's me close the throttle more at idle and give the idle mix screws more affect.

Either way .... you have to unplug the vacume advance canister when setting timing to totally eliminate any effect of vacume on your settings. Even with ported vacume, if because of other things, the throttle idle screw is set too far in and that ported slot is uncovered, will advance the timinng.

Last edited by tbear853; 12-05-2011 at 04:06 PM. Reason: cleaned up

#13

... etc ...

And for the icing on the cake here is proof that ported and full manifold sources pull a nearly identical vacuum, at any time except idle.

http://www.gofastforless.com/ignition/vacuum_chart.jpg

As you can see they follow each other very closely except when you see the throttle position go to 0.

And for the icing on the cake here is proof that ported and full manifold sources pull a nearly identical vacuum, at any time except idle.

http://www.gofastforless.com/ignition/vacuum_chart.jpg

As you can see they follow each other very closely except when you see the throttle position go to 0.

#14

That was a very impressive essay, montana_highboy. I think I will award you a positive rep for that, but I can't give you anymore for a while, so I will give one to sw1tchfoot who was good enough to give us an illustrated graph. .  I am not sure if it is all true and if I agree with it, but it is very well written, thought out, and makes sense. I especially liked this part:

I am not sure if it is all true and if I agree with it, but it is very well written, thought out, and makes sense. I especially liked this part:

I see new people join these threads all the time thinking that their low compression, smog head motors will magically turn into a race car if they buy an MSD racing ignition or some other Ebay GM-styled Chinese junk distributor with a billet shaft and shiny red cap. Most of these guys just understand that a race car has completely differently needs than a street-driven vehicle.

For grins, I actually tried to run my truck on full manifold vacuum, but I couldn't get the idle to come down far enough and no matter where I set it, the automatic transmission would SLAM into gear. Then the idle would be off again from where I just set it. I set it back to ported vacuum (with a ported vacuum switch) and idled it back down, and the truck is absolutely perfect and smooth. This is with a highly modified motor (see my signature below) with all emissions stripped off of it. The distributor was custom-curved to my carburetor, camshaft profile, heads, and compression. Why would it do that, if manifold vacuum is what it really needs? And I don't really understand WHY a vehicle would even need vacuum advance at all if it is sitting still at idle?

I am not sure if it is all true and if I agree with it, but it is very well written, thought out, and makes sense. I especially liked this part:

I am not sure if it is all true and if I agree with it, but it is very well written, thought out, and makes sense. I especially liked this part:

Originally Posted by montana_highboy

What about the Harry high-school non-vacuum advance polished billet "whizbang" distributors you see in the Summit and Jeg's catalogs? They're JUNK on a street-driven car, but some people keep buying them because they're "race car" parts, so they must be "good for my car" - they're NOT. "Race cars" run at wide-open throttle, rich mixture, full load, and high rpm all the time, so they don't need a system (vacuum advance) to deal with the full range of driving conditions encountered in street operation. Anyone driving a street-driven car without manifold-connected vacuum advance is sacrificing idle cooling, throttle response, engine efficiency, and fuel economy, probably because they don't understand what vacuum advance is, how it works, and what it's for - there are lots of long-time experienced "mechanics" who don't understand the principles and operation of vacuum advance either, so they're not alone.

I see new people join these threads all the time thinking that their low compression, smog head motors will magically turn into a race car if they buy an MSD racing ignition or some other Ebay GM-styled Chinese junk distributor with a billet shaft and shiny red cap. Most of these guys just understand that a race car has completely differently needs than a street-driven vehicle.

For grins, I actually tried to run my truck on full manifold vacuum, but I couldn't get the idle to come down far enough and no matter where I set it, the automatic transmission would SLAM into gear. Then the idle would be off again from where I just set it. I set it back to ported vacuum (with a ported vacuum switch) and idled it back down, and the truck is absolutely perfect and smooth. This is with a highly modified motor (see my signature below) with all emissions stripped off of it. The distributor was custom-curved to my carburetor, camshaft profile, heads, and compression. Why would it do that, if manifold vacuum is what it really needs? And I don't really understand WHY a vehicle would even need vacuum advance at all if it is sitting still at idle?

#15

,my take on it is pretty much the same as yours above, it's a very well written and thought out piece, but i'm not sure i buy into it entirely, i just don't understand the need or desire to run an additional 12-15 degrees of advance at idle, in the past i've "tuned" my motor for manifold vacuum but always revert back to ported, it works best for me.

,my take on it is pretty much the same as yours above, it's a very well written and thought out piece, but i'm not sure i buy into it entirely, i just don't understand the need or desire to run an additional 12-15 degrees of advance at idle, in the past i've "tuned" my motor for manifold vacuum but always revert back to ported, it works best for me.