99-04 super duty leaf spring lift in 71 f250

#421

#422

Kinda excited to see if my steering box holds up with the psc assist, Kinda think it will. But if not I'm going to send mine to redhead as well. Herd they will install a bearing in the end of the shaft and will eliminate the movement that takes out the seal....

Crazed I sure hope santa brings you what you wish for, I'm thinking he should bring me the short shifter Pictured above lol But I wont hold my breath, That could hurt...

Crazed I sure hope santa brings you what you wish for, I'm thinking he should bring me the short shifter Pictured above lol But I wont hold my breath, That could hurt...

#423

Been reading through the thread the last few days so as to catch up. Nice project for sure.

I'm interested to see what your fuel system consists of as I'm getting ready to run mine (if Santa reads my list at least!).

Also I've always wanted to dump the vacuum pump like you're doing. Do you know who makes the hydro mount that you got? Is this a stock part that was offered on a cummins configuration somewhere or aftermarket? As you can probably tell, I haven't looked into this much yet.

I'm interested to see what your fuel system consists of as I'm getting ready to run mine (if Santa reads my list at least!).

Also I've always wanted to dump the vacuum pump like you're doing. Do you know who makes the hydro mount that you got? Is this a stock part that was offered on a cummins configuration somewhere or aftermarket? As you can probably tell, I haven't looked into this much yet.

The vacuum pump is a factory cummins part. But good luck finding one and at a decent price. They are hard to find and most people want a good bit for it. When doing this swap the adapter pump mount and pump gear are the hardest things to get. They come on industrial cummins engines and some 4bt's the pump itself can be had at your local napa or other good parts store as long as they can use books to cross reference and not rely on computers. I want to run a vickers pump if I can find one for a decent price. Which brings up a question of my own.

Zach is your pump adapter the same as mine that you have for your vickers pump? Also what PSI and flow numbers is it rated at?

#424

Was your truck already equipped with Power steering from factory? And you just used that box in your current setup? I talked to PSC awhile back when first starting my setup. And they said the steering box will handle the assist. I think the ram is rated at 1,500-1,600 psi and the ford box won't blow a seal. I asked if they would rebuild my box and machine for the bearing but they don't do the machining. So I'm going to get my box rebuilt by redhead while it's getting rebuilt I'm having them drill/tap it for the assist and port the box for additional flow to the cylinder assist. (You Might want to look into that) I'm using the 1979 f250 4x4 box I know they have the issue with the seals constantly leaking due to the lack of a needle bearing. But I didn't know if that was a problem in the 2wd box's as well?

The vacuum pump is a factory cummins part. But good luck finding one and at a decent price. They are hard to find and most people want a good bit for it. When doing this swap the adapter pump mount and pump gear are the hardest things to get. They come on industrial cummins engines and some 4bt's the pump itself can be had at your local napa or other good parts store as long as they can use books to cross reference and not rely on computers. I want to run a vickers pump if I can find one for a decent price. Which brings up a question of my own.

Zach is your pump adapter the same as mine that you have for your vickers pump? Also what PSI and flow numbers is it rated at?

As for the pump and adapter, Ill Have to look back I should have some Good picks of both before I installed them. With number stamped as well. If I recall the feller I got the pump from had It built for the for ford box pressures, I had this all written down at some point Just track it down at the moment. Ill try to find some pictures of what I have and post them up. But Yes as far as I know the adapters are the same and quiet hard to get your hands on.

#426

Thanks it's taking longer then I hoped but it's getting there. I'm running a custom fuel system. I posted everything I have collected so far in previous pages. Mostly just need the fuel pump and misc fittings for my return. Have the aluminum fuel cell on the previous page and am deciding if I want to run a second cell or not for extra capacity. Thinking I'll set it up close to this. Run -10AN line from cell(s) to a 100 micron water seperator and into a Aeromotive A1000 pump then -10 line to a 3 micron fuel filter then -8 line to a Y fitting tapped for a fuel pressure sensor. And then -8 from the Y to a dual feed into the P Pump. I will be blocking off the stock lift pump but will carry it with other spare parts incase the A1000 gives out. I can mount the lift pump on the block and use the existing Y fitting in the system to tie in the stock pump to limp off the trails with. I'm running a regulated return setup.

The vacuum pump is a factory cummins part. But good luck finding one and at a decent price. They are hard to find and most people want a good bit for it. When doing this swap the adapter pump mount and pump gear are the hardest things to get. They come on industrial cummins engines and some 4bt's the pump itself can be had at your local napa or other good parts store as long as they can use books to cross reference and not rely on computers. I want to run a vickers pump if I can find one for a decent price. Which brings up a question of my own.

Zach is your pump adapter the same as mine that you have for your vickers pump? Also what PSI and flow numbers is it rated at?

The vacuum pump is a factory cummins part. But good luck finding one and at a decent price. They are hard to find and most people want a good bit for it. When doing this swap the adapter pump mount and pump gear are the hardest things to get. They come on industrial cummins engines and some 4bt's the pump itself can be had at your local napa or other good parts store as long as they can use books to cross reference and not rely on computers. I want to run a vickers pump if I can find one for a decent price. Which brings up a question of my own.

Zach is your pump adapter the same as mine that you have for your vickers pump? Also what PSI and flow numbers is it rated at?

I am running -8AN stuff & 1/2" line from the my custom aluminum tank to the factory lift pump. Probably adding a pressure gauge in there somewhere. Probably using one of these if I do it: GDP PushLok Fuel Pressure Sender Tee 3/8" & 1/2"

I bought the filter base and am doing the dip tube/draw straw in it like in the 1st filter in this thread:

DIY Fuel/Water/Air Separator/Accumulator - Dodge Cummins Diesel Forum

I am debating on running the return from the top of the filter plate like he did.

How are doing the regulated return setup?

I am just running a 5/16" / -6AN return from the pump.

Also, thanks for the info on the pump & bracket.

#427

I guess I worded that oddly. I saw the pic(s) of some parts for the fuel system & am interested on how you will put it together. Your rundown above makes sense though.

I am running -8AN stuff & 1/2" line from the my custom aluminum tank to the factory lift pump. Probably adding a pressure gauge in there somewhere. Probably using one of these if I do it: GDP PushLok Fuel Pressure Sender Tee 3/8" & 1/2"

I bought the filter base and am doing the dip tube/draw straw in it like in the 1st filter in this thread:

DIY Fuel/Water/Air Separator/Accumulator - Dodge Cummins Diesel Forum

I am debating on running the return from the top of the filter plate like he did.

How are doing the regulated return setup?

I am just running a 5/16" / -6AN return from the pump.

Also, thanks for the info on the pump & bracket.

I am running -8AN stuff & 1/2" line from the my custom aluminum tank to the factory lift pump. Probably adding a pressure gauge in there somewhere. Probably using one of these if I do it: GDP PushLok Fuel Pressure Sender Tee 3/8" & 1/2"

I bought the filter base and am doing the dip tube/draw straw in it like in the 1st filter in this thread:

DIY Fuel/Water/Air Separator/Accumulator - Dodge Cummins Diesel Forum

I am debating on running the return from the top of the filter plate like he did.

How are doing the regulated return setup?

I am just running a 5/16" / -6AN return from the pump.

Also, thanks for the info on the pump & bracket.

#428

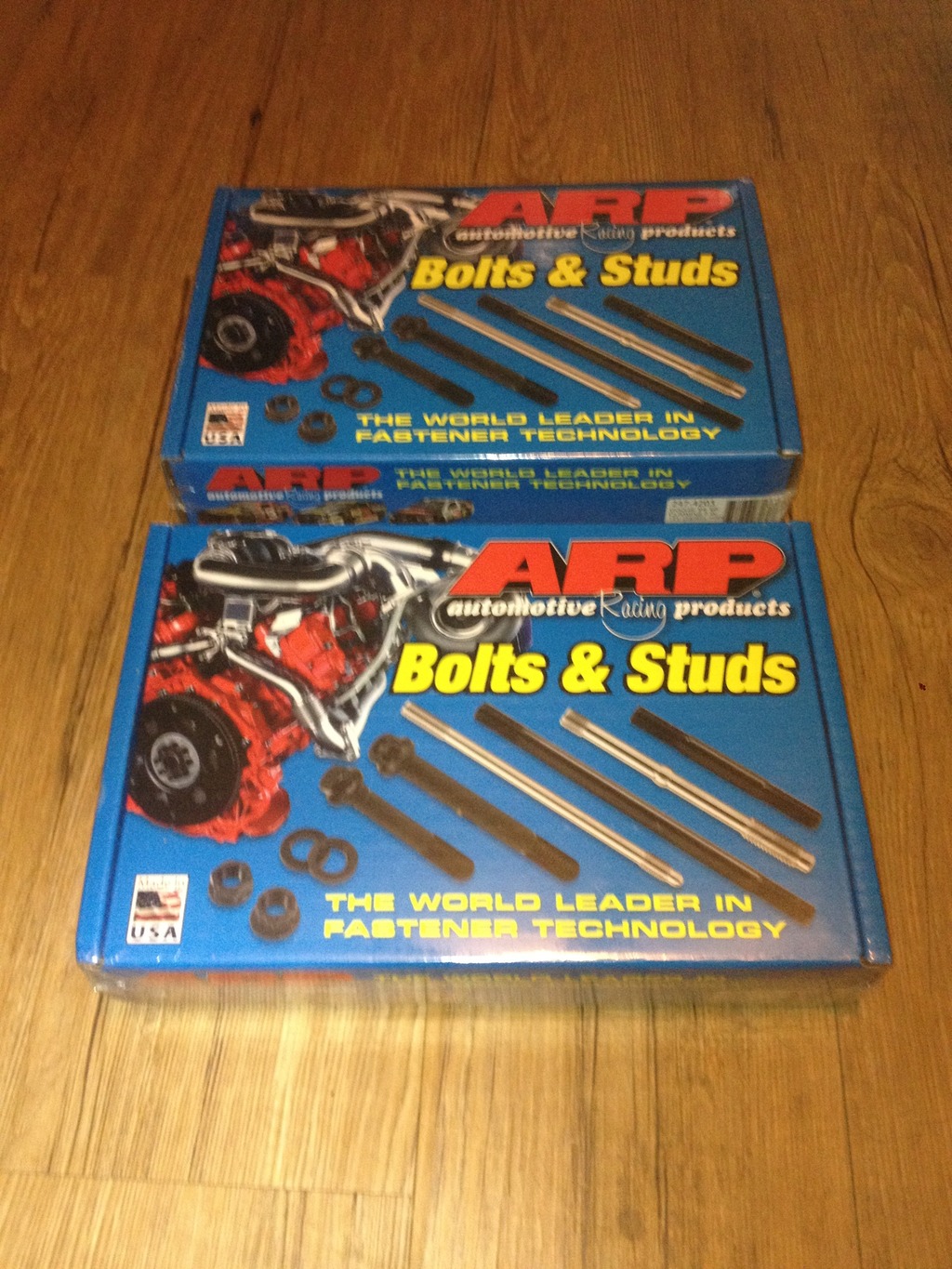

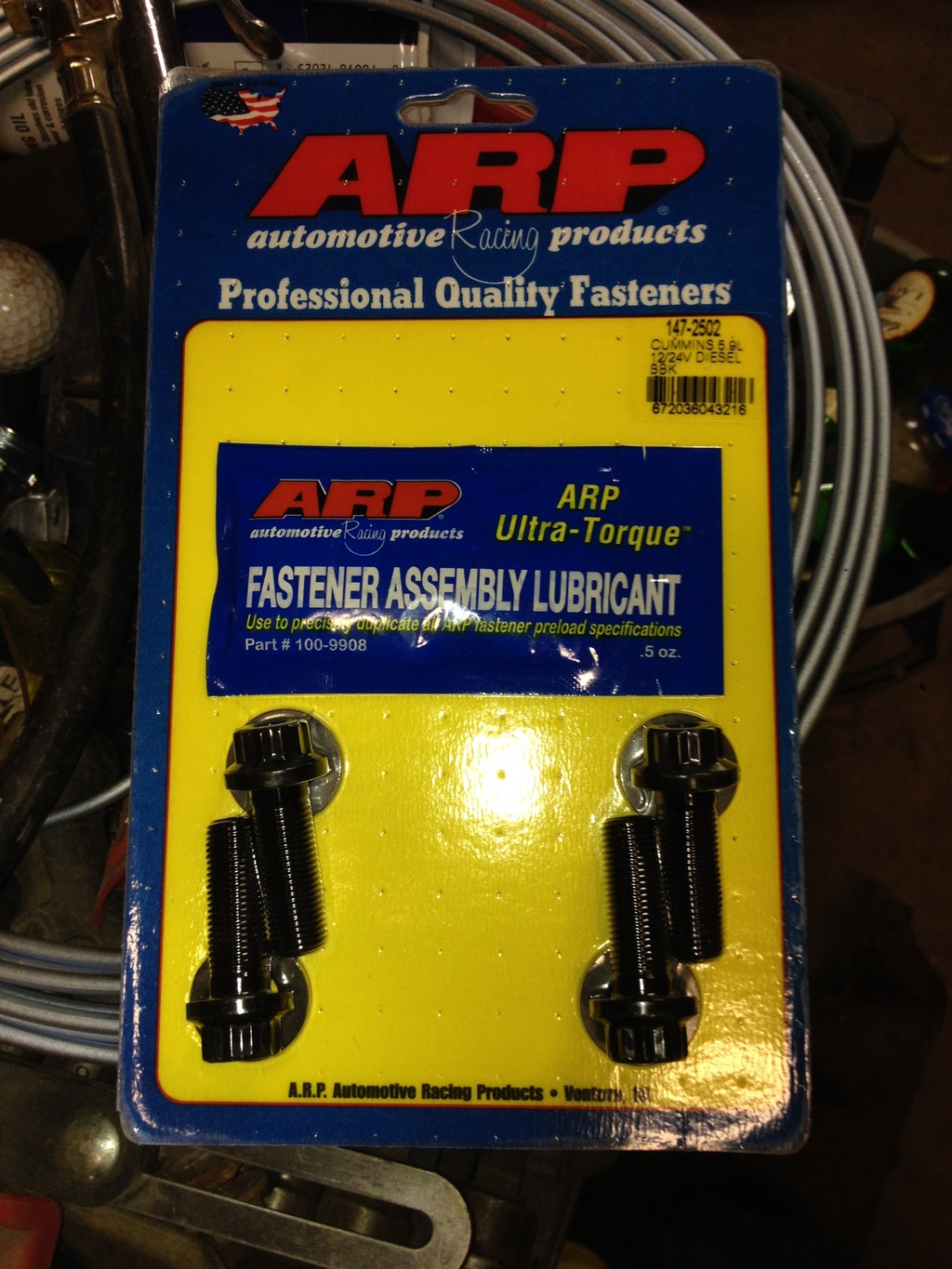

Trying to keep a decent time line on this build. So I can look back through and have all the updates in order and not leave anything out. This post will bring me up to mid November. I'm finally getting some decent shop time in now that it's winter. I decided to treat myself to some early Chrustmas presents for myself. Got 2 sets of ARP head studs one set for the crew cab and the other for my daily driver dodge cummins that has a leaky head gasket so I figured I'll replace the head studs with new ones when I get to working on it. Also got ARP balancer bolts, Hamilton valve springs and retainers, PAC brake 4 and 5k springs and a fuel fitting, NV4500 5th gear nut fix and turbo exhaust flange so I can make my downpipe

#429

#430

Haha yup they were having a sale and I figured mise well treat myself and get it while the sale was going on. I been hearing Christmas music for the past couple weeks as I'm still waiting on my main Xmas present to arrive yay should be here next week will post pics when it arrives!!

#431

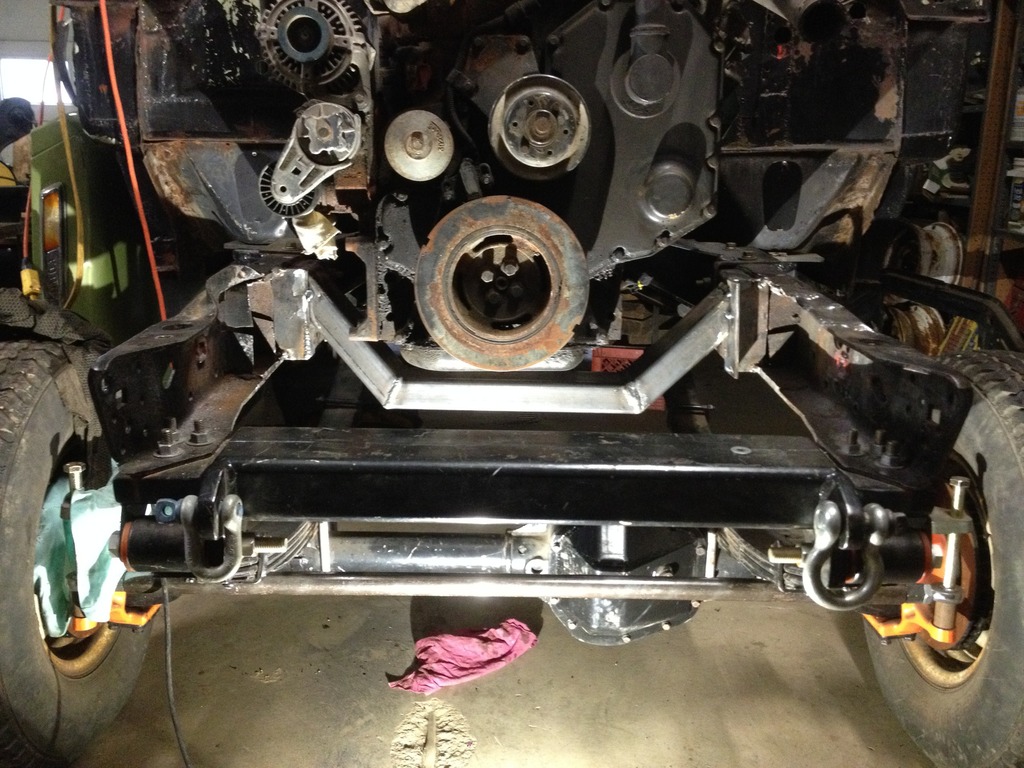

Finally after a summer of being busy on other stuff. And stocking up on parts it was time to get some much needed time on the crew. This is back at the end of November and into December. Got the stock engine crossmember cut out since it needed cut for the cummins and power steering there wasn't much left of it. So I made a new one in it's place and boxed in the frame rails then wire wheeled and painted the frame black. I still want to make a bottom plate on the crossmember to tie it all in more. But I got to figure out how I want to do my steering incase I want to incorporate something in it.

Old one cut out

Test fitting

Engine out for final time hopefully

Old one cut out

Test fitting

Engine out for final time hopefully

#433

I hope it's the final time. While the engines out it's getting resealed some performance goodies and a fresh coat of paint. Hopefully if I can keep getting shop time the engine will be back in it's home in a month or so. Need to get the head off and sent to a machine shop to get checked for flatness. Right now I'm sanding the frame and underside of cab for paint and bedliner. I'll post pics when I get a chance. Along with the Xmas present that finally arrived. Y'all should like it.

#434

Finally all caught up on the updates. Spent the last week scraping the old flaking undercoating off the bottom of the cab and frame. I can't feel my arms anymore from all the work getting that stuff off. But now I'm ready to prep the cab for paint and undercoating and frame will get sprayed with black chassis saver. Hope to have it done this weekend if things go as planned.

Don't have enough ceiling height to completely flip the cab back so this got to do.

After the first 2 days of scraping the old gunk off

Finally got it all off man where the floor was coated it held up well

The pile of undercoating after I finished

Don't have enough ceiling height to completely flip the cab back so this got to do.

After the first 2 days of scraping the old gunk off

Finally got it all off man where the floor was coated it held up well

The pile of undercoating after I finished

I wish I was on final time....

I wish I was on final time....