99-04 super duty leaf spring lift in 71 f250

#167

Yea Im known to be full of surprises haha I think it's mostly my indecisive personality after how many rears I think this ones staying. Now I need to get rid of that Dana 70 to get some more funds for the ole beast. Haven't had a chance to get anything done on the crew this past week been busy with other projects won't get anything else done until next week. I'm cutting it close this Saturdays the first diesel sled pull of the season and still got lots to do to get ready change tires add a bd rad box out on my tunnel ram intake build a u joint shroud and some other things hope its done in time couldn't work on it today it was raining and probably again tomorrow so that really puts a time limit on me was talking to a 3rd gen dodge guy and they said that the lug pattern is the same 8x6.5 on the AAM as the older axles but only difference is the lugs are bigger diameter on the AAM's and they seen 1st and 2nd gen dodges running 3rd gen rims. Haven't confirmed this yet when it's decent weather outside ill go try using a ford 8 lug rim on my new axle and see if it fits would make things easier if they went on. Just don't get why all the info I've read on this axle they all mention a lug pattern change to metric

#168

Wasn't raining for Alittle so I was taking measurements on my dodge to get some tubing to make the u joint shields but now I'm having a hard time finding some tubing nobody has any or else they want a fortune for just a foot of 6" pipe ill post more on this when I get some materials to build them. I figured I'd see if a 8x6.5 wheel would fit on the aam axle and it does so I should be good there without messing with a lug pattern change. I may try matching the front Dana 60 lugs to the same size as the rear axle so they are all the same. Here's proof a 8x6.5 rim fits newer dodge axles so much mixed info online hope this clears it up for others wanting to do a similar setup.

#169

I'd like to get the frame and all brackets that I can powder coated maybe the axles but I may just paint them as they will get scraped up anyways all steering linkage most the parts besides body pretty much. Yea my favorite color is black but I don't want to may projects to be black so I may do a flat black or grey color instead.

Tinstar36 can't you run the caliper on the axle instead of on the back of the 205?

Tinstar36 can't you run the caliper on the axle instead of on the back of the 205?

#170

i missed this as well. thats good to know about the lug pattern. a friend of mine has a couple am axles out of the newer dodges that he want to give me or should i say suck me in on some trade work for... lol now i really need to think about what im gonna do. sounds like you have your plate of projects as full as you can stack it once again.  seems like any steal is getting expensive these days although i am looking forward to seeing you u joint shield. thats somethin i have never really thought about. but its a great idea.

seems like any steal is getting expensive these days although i am looking forward to seeing you u joint shield. thats somethin i have never really thought about. but its a great idea.

seems like any steal is getting expensive these days although i am looking forward to seeing you u joint shield. thats somethin i have never really thought about. but its a great idea.

seems like any steal is getting expensive these days although i am looking forward to seeing you u joint shield. thats somethin i have never really thought about. but its a great idea.

#171

i missed this as well. thats good to know about the lug pattern. a friend of mine has a couple am axles out of the newer dodges that he want to give me or should i say suck me in on some trade work for... lol now i really need to think about what im gonna do. sounds like you have your plate of projects as full as you can stack it once again.  seems like any steal is getting expensive these days although i am looking forward to seeing you u joint shield. thats somethin i have never really thought about. but its a great idea.

seems like any steal is getting expensive these days although i am looking forward to seeing you u joint shield. thats somethin i have never really thought about. but its a great idea.

seems like any steal is getting expensive these days although i am looking forward to seeing you u joint shield. thats somethin i have never really thought about. but its a great idea.

seems like any steal is getting expensive these days although i am looking forward to seeing you u joint shield. thats somethin i have never really thought about. but its a great idea.

#172

Yeah not a good thing to use a dd for anything but a dd I have my mileage getter and it killed a water pump so I am diving my work truck.

That will be good maybe with that at the end of this year you well have this round of mods done and drive it just long enough to find out what the next set is.

That will be good maybe with that at the end of this year you well have this round of mods done and drive it just long enough to find out what the next set is.

#173

looks good. ya get that manual swap done and you should be able to do all the pulling in the world. im a fan vrs auto for sure. i know i keep tossing it back and forth as well. i would rather just buy the am from this guy, cause hes kinda sneaky like that but he wont sell it to me, he will give it to me in return for help on his project. ha ha i really just want to work on my own project. how does your u joint shield fit to your axle?

#174

I'm deciding what I want to do for my DD a built auto is nice mine was built but my PMC was bad not allowing converter lockup by time I finally figured out it was the PMC the damage was done I think it's just my torque converter that may be bad its 50/50 right now between the auto vrs stick. I'm not sure yet how I want to mount the u joint shields I have 2 ideas first is to drill 3 holes through the end if the pipe evenly spaced and run bolts down through and will tighten around the yoke snout the second is to weld some angle to the side of the pipe and bolt it to the pumpkin. If I were you I'd keep harassing him to sell the AAM to you lol. Your runnin a Dana 80 now converting to discs I believe? Main reason I went with the AAM was for the park brake seems to be the best option for one in my truck.

#175

Alright time for a small update started to get my lower radiator mount made up. I was going to make it a bolt in ordeal but didnt want to sleeve the radiator support but probably would have if I was using the correct 67-72 core support but I'm using a 73-79 so im welding it right to the back side of the support as they are easy to get another one. Still got to weld it to the support and cap the sides of the radiator support and probably tie them into the sides of where the stock ford radiator would mount. Also got some goodies to put my AAM axle in it finally and some misc brackets and longer shackles to try stopping my stock SD shackles from hitting the springs before full travel. I got the AAM spring perches cut off and ground down can I say that is an absolute b**** getting them off just got to drill the leaf spring perches center bolt bigger to fit my SD springs and weld up some axle tube pitting was only bad on the drivers side enough with the typing on with the pics

Layout of the lower radiator mount

Some goodies

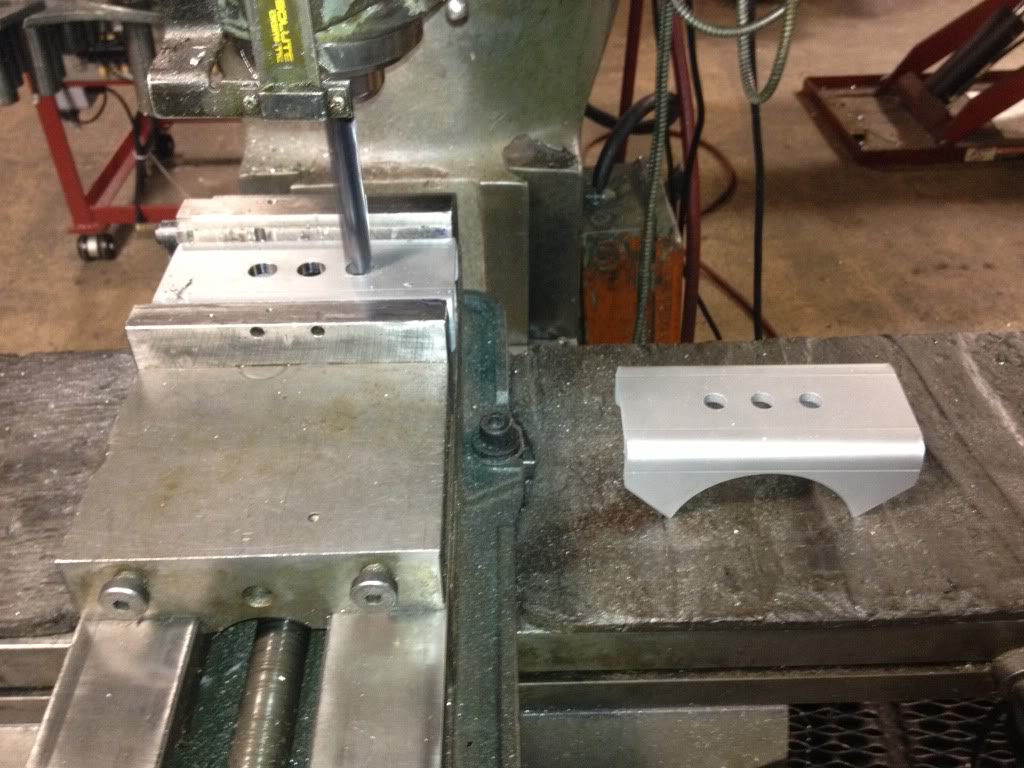

Drilling out the top u bolt plate to fit over my center leaf bolt

Layout of the lower radiator mount

Some goodies

Drilling out the top u bolt plate to fit over my center leaf bolt

#176

hey thats looking sharp. i like how your doing your radiator support, so does the 73-79 support bolt right up? or do u need to do mas change? your getting there. i wish i was as far on my engin compartment. im not familiar with the autos as much, but that same kid with the p pump conversion had some toggle that he had ran to put the converter in full lock up. but he also smoked about 4 build tranys, thats pretty much why he sold the truck. couldnt keep his foot off the go pedal.

as for the aam im really up in the air still. im running a 14 bolt right now. i also have a full disk conversion for it. i have the big chevy calipers. but as we all know the elderado are smaller but you can have use of the e brake. so leaves me very few options. ive never seen a pinion brake on the back of a np241 not to say there not out there. remember some of the old scouts had them on the pinion and they went down the highway just fine? or a line lock. but for one im not sure if that will pass inspection for one. and i dont know how reliable it is. also dont know if i want to run a brake line into the cab up under the dash. sounds like a mess if something ever went wrong.

as for the aam im really up in the air still. im running a 14 bolt right now. i also have a full disk conversion for it. i have the big chevy calipers. but as we all know the elderado are smaller but you can have use of the e brake. so leaves me very few options. ive never seen a pinion brake on the back of a np241 not to say there not out there. remember some of the old scouts had them on the pinion and they went down the highway just fine? or a line lock. but for one im not sure if that will pass inspection for one. and i dont know how reliable it is. also dont know if i want to run a brake line into the cab up under the dash. sounds like a mess if something ever went wrong.

#177

The 73-79 support is almost a bolt in the stock radiator mounts are different but I ain't using them anyways also some of the inner fender bolt holes are off but can be fixed by new holes with clips installed and I'm not sure if its just my outer fenders being out of whack or not but they have Alittle gap here and there where the fender bolts to the core support. Ill figure it out more when body work comes just hoping I don't need to swap out for a 67-72 support in the end. I've voted against the eldorado calipers to many people weren't impressed with them. A line lock can be nice for certain times but I don't like the risk of the brakes leaking down pressure having lines into the cab and constant pressure on the brake system leading to pre mature wear. I've searched on pirate4x4 about t case brakes there's only one real place I know of that makes a np205 kit and it gets expensive you need to buy the e brake kit and there yoke to mate up by time you add it up its over double what I paid for my AAM axle and you get a beefier axle out of the deal to. Also to many complaints about the caliper they use you can't buy replacement pads and constant adjustment to keep it holding also some said there's wore from high speed driving (daily driving) but a trail only vehicle you don't have to worry about it.

#178

ya i hope you dont have to change it after all the work your going to put into it. ha ah your lovin your new welder arent ya  man i dont know what to do. i wonder if a rotor could be machined out for a guy??? build your own bracket and just run an eldarado caliper????? but the you still have wear factor going down the highway. hell i dont know. probably just run the aam and put 3.73s in the dana 60 front. ill have to check into it before i do make sure you can get them for the d60. also im a fan of ballistic fab my self.

man i dont know what to do. i wonder if a rotor could be machined out for a guy??? build your own bracket and just run an eldarado caliper????? but the you still have wear factor going down the highway. hell i dont know. probably just run the aam and put 3.73s in the dana 60 front. ill have to check into it before i do make sure you can get them for the d60. also im a fan of ballistic fab my self.

man i dont know what to do. i wonder if a rotor could be machined out for a guy??? build your own bracket and just run an eldarado caliper????? but the you still have wear factor going down the highway. hell i dont know. probably just run the aam and put 3.73s in the dana 60 front. ill have to check into it before i do make sure you can get them for the d60. also im a fan of ballistic fab my self.

man i dont know what to do. i wonder if a rotor could be machined out for a guy??? build your own bracket and just run an eldarado caliper????? but the you still have wear factor going down the highway. hell i dont know. probably just run the aam and put 3.73s in the dana 60 front. ill have to check into it before i do make sure you can get them for the d60. also im a fan of ballistic fab my self.

#179

New welder has done me so much for all the random things I do. But still struggling getting it dialed in has so many different settings you can adjust. I've seen some custom brakes made up like your sayin and weren't half bad either. But in the end I'm thinking this is the best axle for my build. You can get a 3.73 ratio in a Dana 60 that's the only downfall with the AAM can't run 3.55 but again I don't believe ill have any use for that gear ratio in this truck with 40-42" tires you may want to check into the 01-02 dodge Dana 80's discs drum in hat e brake and 3.55 gears available. Here's some work I got done in the axle it's about ready to bolt in. Just need to grind down the weld I laid on the axle tube where the leaf perch was had a good size pit for my liking. Got the new mounts drilled out to fit over the leaf center bolt.